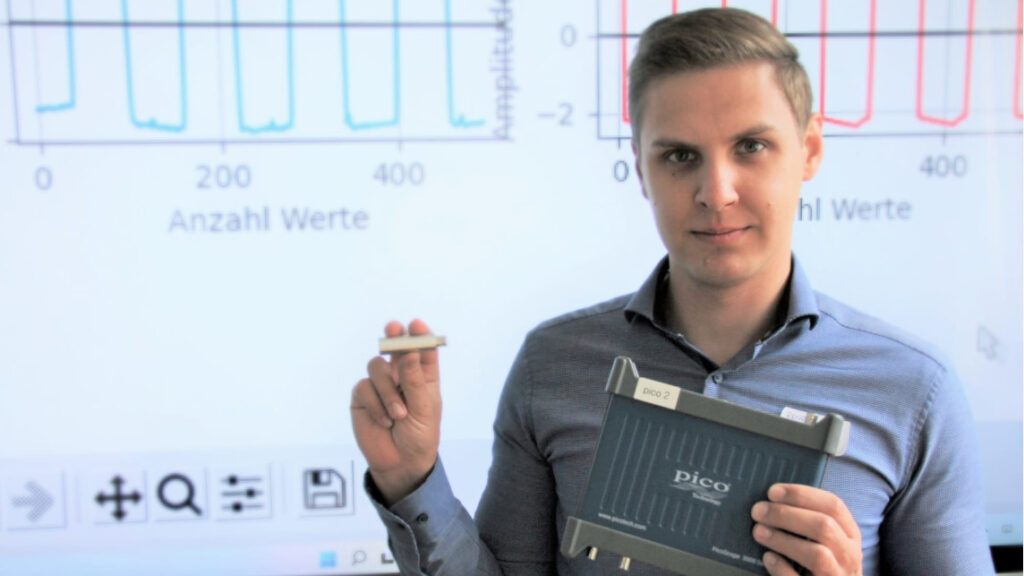

The development of oscilloscopes is the speciality of Auto-Intern (AI), consortium partner in Car Repair 4.0. René Glitza, Chief Project Officer (CPO) at the manufacturer of PC-based hardware for electronic vehicle diagnostics, presents the proof of concept of the further developed omniscope and the E-field sensor.

By Ralf Schädel, IT Editor and Project Manager Cloud Services and Gaia-X at eco – Association of the Internet Industry

Many car repair shops use a so-called picoscope for accurate oscilloscope measurements. This has proven to be a very good and accurate measuring device in daily use. Relatively high acquisition costs, difficulties in setting up the device – because it is operated via the software and is very complex with many setting options – have inspired René Glitza’s development team to develop a smaller, more robust and easier-to-operate oscilloscope.

Step by step to further development

The single-channel oscilloscope initially created as part of the Car Repair 4.0 project meets precisely these requirements. “It’s waterproof and you could drive over it with a car,” Glitza assures. Signals are possible with it in sufficiently good quality. Equipped with user-friendly software, it is as easy to handle as a spanner. In the next step, AI has now produced a further developed omniscope, which can be connected with or without direct copper contact, for example to the battery or sensor cable .

Omniscope developed with E-field sensor

The innovation: A live cable only has to be held to this sensor, which looks like a clothes peg. Current oscilloscopes only have so-called measuring tips or clamps, with which the current in the cables can be measured without feedback. These measuring tips correspond to an analogue front end that is connected via copper contacts. The prototype of the patented E-field measurement sensor, which AI presented at the end of October as part of the Car Repair 4.0 milestone meeting at the Osnabrück University of Applied Sciences on the other hand, simply and non-invasively converts voltages into digital signals via the emitted electric field using diagnostic software. The innovation: “It no longer needs to have contact via the copper connections, but only needs to lie on the part to be measured,” explains Glitza. Another innovation is that several omniscopes can be connected to a computer via USB and the signals can be synchronised using a patented process. It is, therefore, an expandable, dynamic multi-channel oscilloscope or omniscope. Compared to the multi-channel measuring instruments commonly available on the market, it represents a more cost-effective variant. “The car repair shop employee simply takes an extra omniscope from the drawer when another channel is needed,” says Glitza.

Prerequisite for AI is created

The Auto-Intern GmbH underlines with this novelty its project mission to produce even more powerful and innovative products and technologies for electronic vehicle diagnostics and artificial intelligence. “We are testing in the proof of concept whether signals can be reconstructed in the measurement method and whether they have the necessary quality,” explains the CPO. This is a necessary prerequisite to be able to teach AI models.

Did you enjoy reading this article? Then subscribe to our newsletter and receive regular updates on related topics and on the Car Repair 4.0 project, and discuss this and similar exciting topics with us on LinkedIn.